SAB Precision - Technology – Innovation

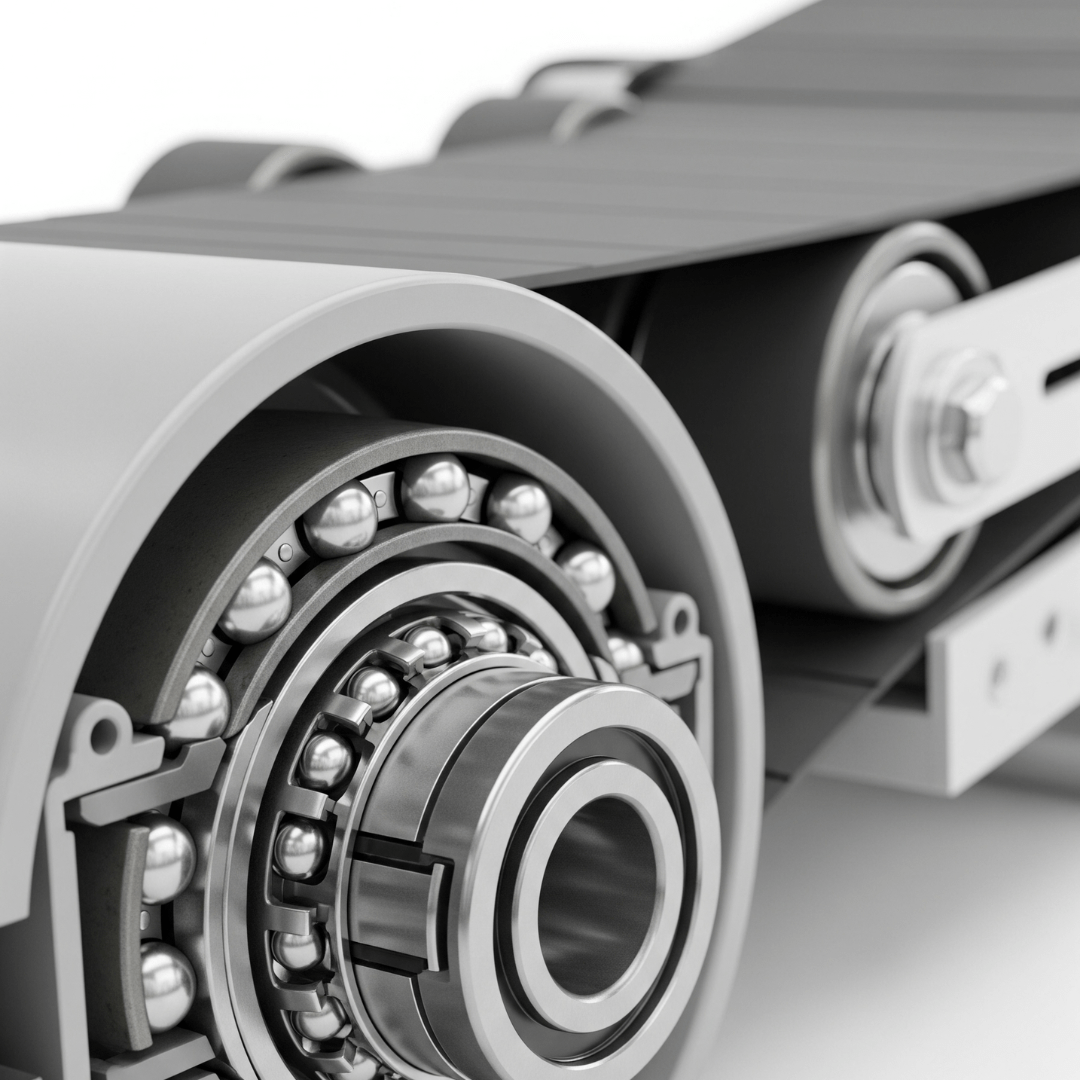

A Reliable Bearing Manufacturer

for Modern Industrial Applications

SAB Bearings is a trusted Indian manufacturer specializing in precision-engineered bearings built to meet the demands of today’s industrial landscape. With advanced production capabilities, strict quality control, and ISO-certified systems, we supply durable, high-performance bearing solutions for sectors such as automotive, railways, and heavy machinery. Our products are designed to perform under extreme conditions, ensuring consistency, reliability, and long operational life. As industries evolve, we continue to upgrade our processes and expand our capacity — delivering bearing solutions that match modern expectations in speed, scale, and standards.

Explore Our Other

Products

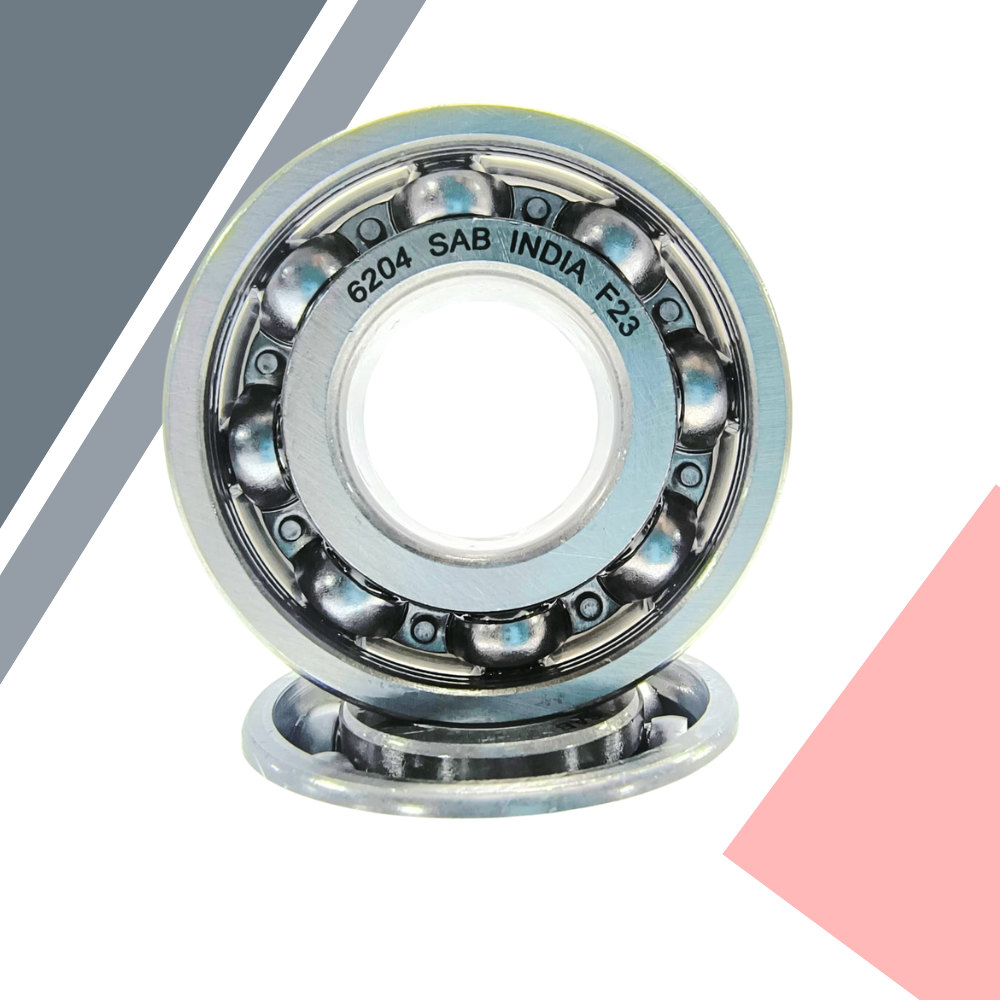

Ball Bearings

Read More ➔.png)

Tapered Roller Bearings

Read More ➔

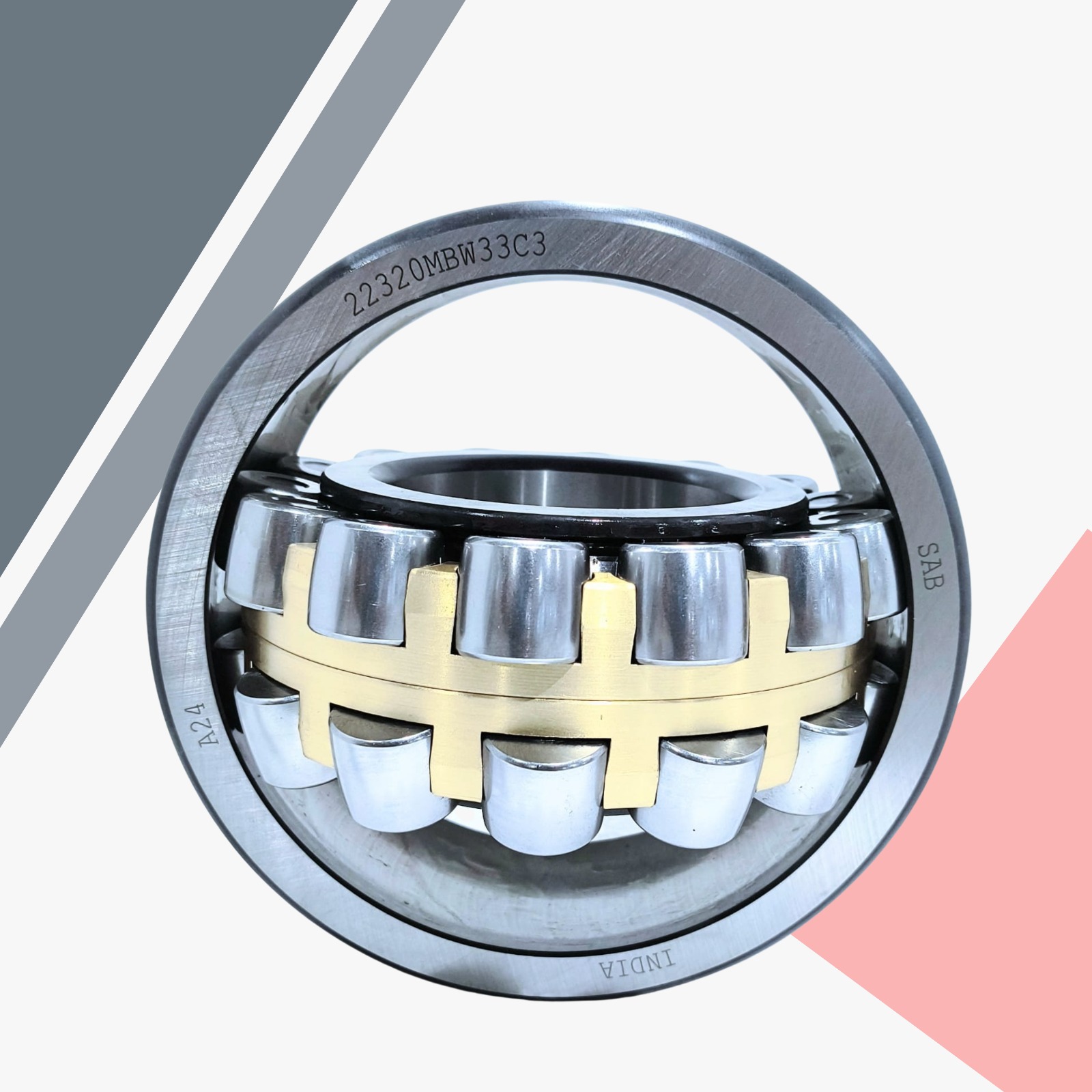

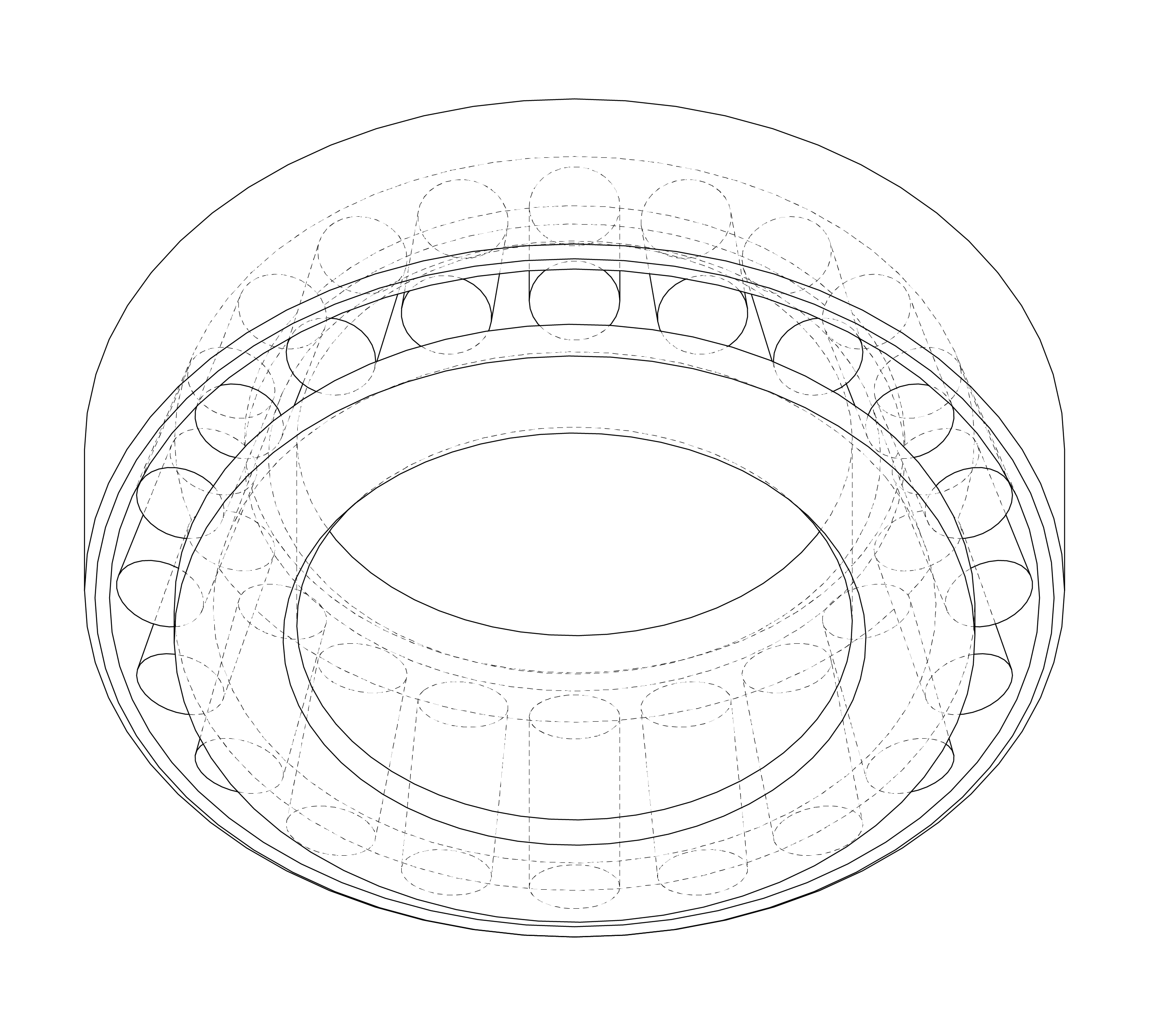

Spherical Roller Bearings

Read More ➔

Cylindrical Roller Bearings

Read More ➔

Thrust Ball Bearings

Read More ➔

Pillow Block Bearings

Read More ➔

Needle roller Bearings

Read More ➔

Self Aligning Bearings

Read More ➔Relentless Focus on Quality, Precision,

and Performance

At SAB Bearings, our commitment to quality runs deep in every stage of production. Through a disciplined, detail-oriented workflow, we ensure each bearing meets the highest standards of reliability and performance.

End-to-End Bearing Solutions: From Engineering to Maintenance

At SAB Bearings, we offer more than just manufacturing. Our services cover the full lifecycle of bearing usage — from product development to after-sales support. We ensure every bearing is engineered for precision, installed correctly, and maintained for long-term performance and cost-efficiency.

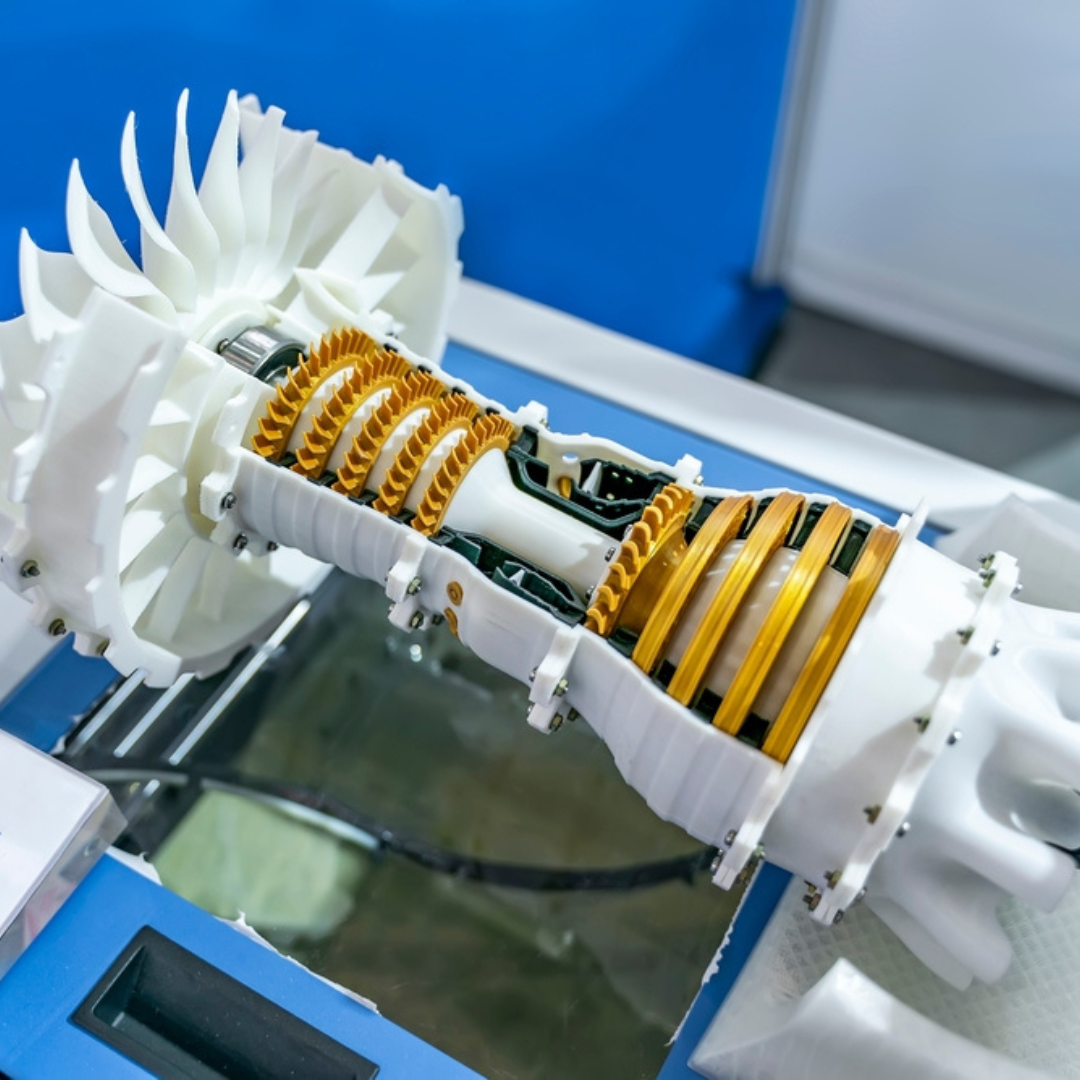

Technical Engineering & Custom Development

We evaluate specific applications and deliver custom-designed bearings suited for load, speed, and environmental demands.

Fitment Support & Maintenance Solutions

Our team provides expert guidance on bearing installation, troubleshooting, and maintenance to reduce wear and operational downtime.

.jpg)

Agriculture – Earthmover – Paper Industry

A Streamlined Manufacturing Approach

Focused on Quality and Precision

At SAB Bearings, every bearing is the result of a disciplined, step-by-step process designed to ensure dimensional accuracy, long service life, and consistent performance. From initial assessment to final inspection, our workflow reflects a commitment to engineering excellence and quality assurance.

Finest Raw Materials

We start with raw material adhering to chemical composition and tolerance as per international norms. It is further cross checked in our factory as per scientifically designed sample plan, in state of the art quality control machine to ensure durability & performance.

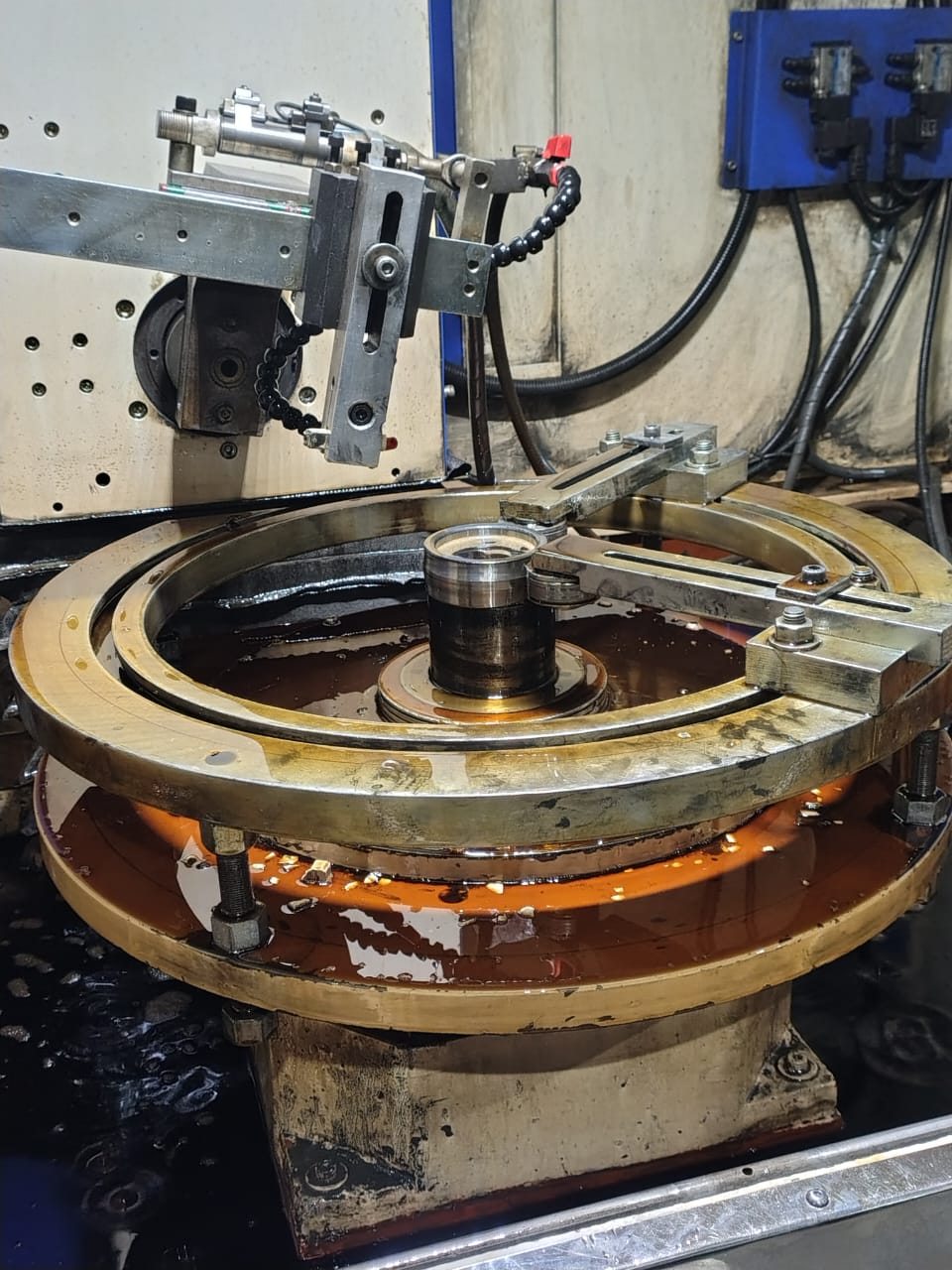

Grinding

Grinding the materials with precision to achieve the perfect shape and size.

Superfinishing & Core Grinding

Enhancing surface quality through superfinishing and core grinding processes.

Bearing Assembly

Assembling components with accuracy for optimal performance.

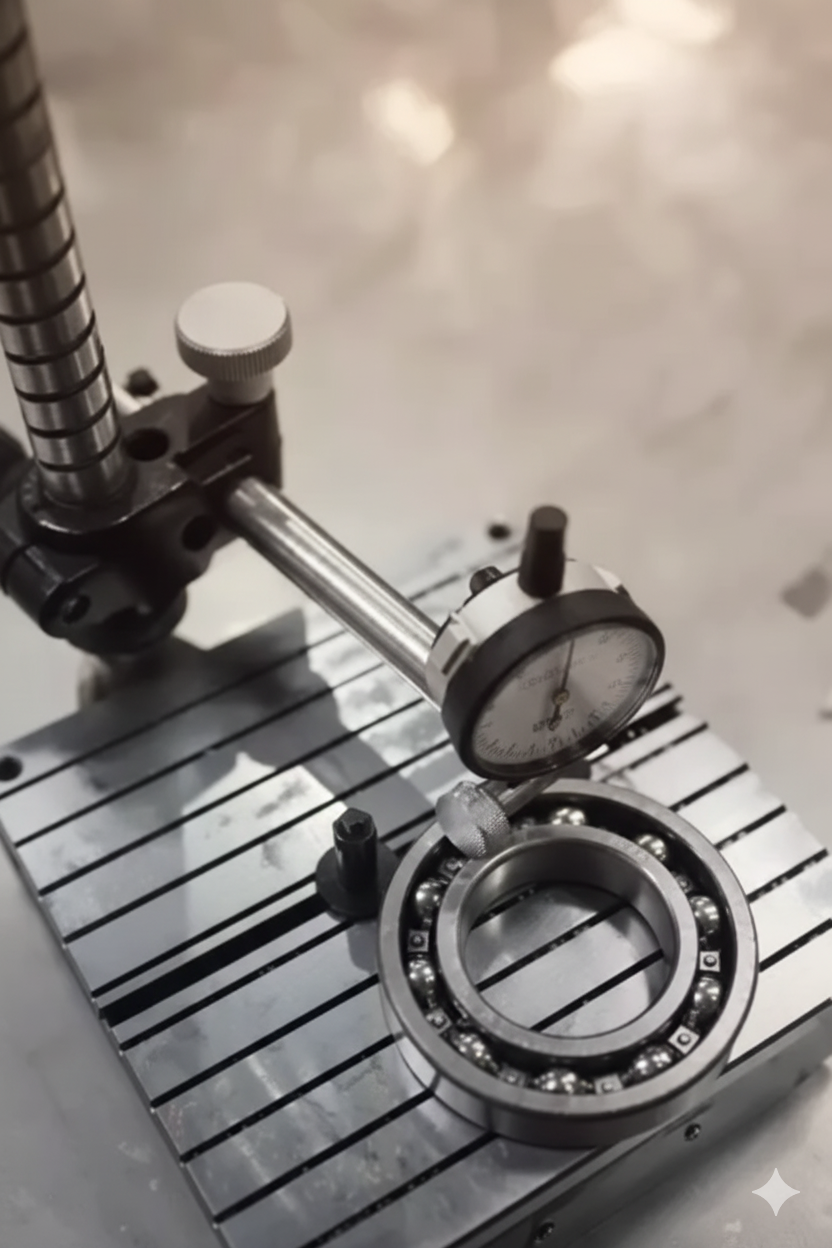

Rigorous Quality Check

After initial quality check and in production quality check, post assembly quality check ensures that bearings meet strict dimensional accuracy.

Final Quality Control

Laster Marking: Laser marking in bearings ensures markings are clear, accurate, well-aligned and durable. It verifies legibility, correct data, and contrast so markings stay readable and resistant to wear, ensuring long-term traceability.

Packaging

Secure Packaging: Secure multi-level packaging to protect the bearings from moisture, dust, manual touch as well as transportation and in stocking at the customer end.

Reliable Bearing Solutions for

Diverse Industrial Needs

Our expertise spans across a wide range of sectors, delivering high-precision bearing solutions tailored to the needs of each industry. From high-speed transportation to demanding industrial applications, our products ensure performance, safety, and reliability.

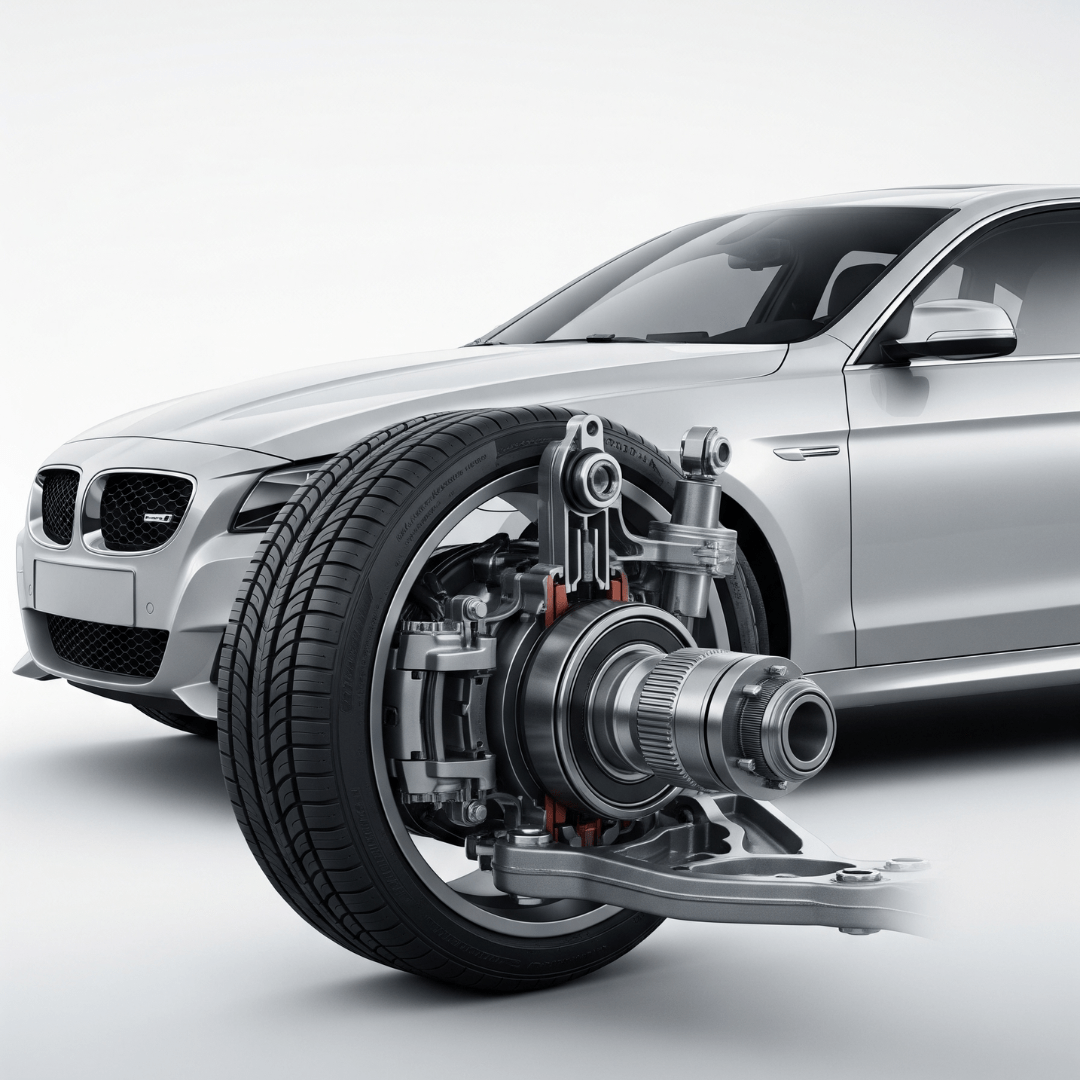

Automotive

We provide robust and efficient bearing systems that meet the performance and durability demands of the modern automotive industry.

- High-speed rotation

- Enhanced durability

- Heat resistance

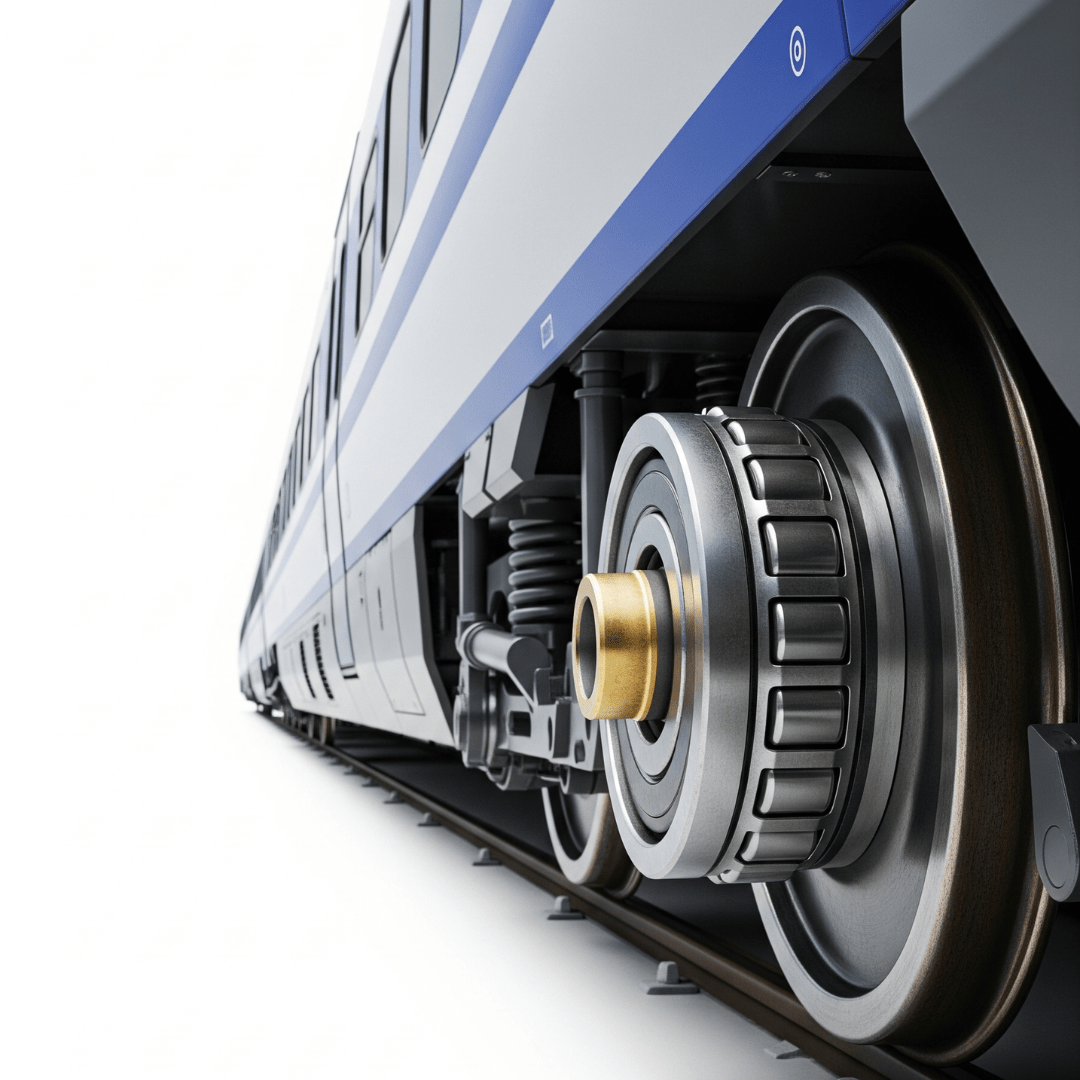

Railway

Our specialized bearings for rail transport are built for stability, safety, and long-lasting performance under heavy loads and tough conditions.

- Vibration control

- Load endurance

- Low maintenance

Material Handling

Reliable solutions for industrial equipment involved in continuous operations such as conveyors, cranes, and lifters.

- Load handling

- Load handling

- Extended lifespan

Heavy Machinery

Designed to handle extreme pressures and continuous usage, our bearings power essential heavy-duty equipment across industries.

- Shock resistance

- Shock resistance

- Dust protection

Bearings in Fan Industry

Reliable bearings ensure smooth, quiet, and energy-efficient fan operation for long-lasting performance.

- Low Friction & Noise: Enables silent and stable fan movement.

- High Durability: Withstands continuous operation and varying loads.

- Energy Efficiency: Reduces power consumption and enhances motor life.

-min.png)

FAQs

FAQ Structure for Bearings

Answer: Mounting a bearing involves several steps:

- 1. Preparation: Ensure the bearing and its environment are clean and free of contaminants.

- 2. Inspection: Check for any visible damage or irregularities.

- 3. Method Selection: Choose the appropriate mounting method (mechanical, thermal, or hydraulic).

- 4. Installation: Carefully place the bearing in position and apply the necessary force or heat.

- 5. Verification: Check alignment and secure the bearing.

Answer: Common tools include:

- Bearing heater or induction heater

- Mounting sleeves or tools

- Hydraulic presses or pullers

- Alignment tools

Answer: Use alignment tools and gauges to check for:

- Axial and radial alignment

- No visible gaps or misalignment

Answer: Dismounting involves:

- 1. Preparation: Ensure safety and gather tools.

- 2. Loosening: Remove any locking devices or seals.

- 3. Dismounting Method: Use mechanical, thermal, or hydraulic methods to remove the bearing.

- 4. Inspection: Check the bearing and components for wear or damage.

Answer: You may need:

- Pullers (mechanical or hydraulic)

- Bearing dismounting tools

- Heat sources like heaters

Answer: Bearing numbers provide information on:

- Type and Series: Identifies the bearing type and design.

- Dimensions: Indicates bore, outer diameter, and width.

- Precision and Load: Provides details on tolerance and load capacity.

Answer: The first digits usually indicate:

- Bearing type (e.g., deep groove ball, angular contact)

- Series and dimensions

Answer: Proper storage includes:

- Environment: Store in a clean, dry place.

- Packaging: Keep bearings in their original packaging.

- Positioning: Store horizontally and avoid stacking to prevent deformation.

Answer: Improper storage can lead to:

- Corrosion or contamination

- Deformation

- Premature failure

Answer: Handle bearings with care:

- Gloves: Wear clean gloves to avoid contamination.

- Tools: Use proper tools to avoid applying force directly to the bearing.

- Surface: Place bearings on clean, flat surfaces.

Answer: Precautions include:

- Avoiding shocks and impacts

- Ensuring cleanliness

- Preventing exposure to moisture and contaminants

Q1: If there is forging or grinding crack recurring in outer ring / inner ring breakage?

Ans: Broken outer or inner rings can occur due to several reasons such as a press fit being too large, the fillet of the roll neck or chock being too large, excessively high impact load, and the development of flaking or burns. To correct these issues, it is essential to select the proper fit, ensure the fillet of the roll neck or chock is smaller than the radius of the rings and improve the loading condition. Also, we need to analyse material crack test report.

Q2: What could cause flaking on one side or symmetrical flank along the circumferential raceway?

Ans: Flaking at one side due to load offsetting or at symmetrical positions along the circumferential raceway can be caused by abnormal axial load or poor roundness of the chock or one side road. The corrective measures include applying clearance fit between the outer ring of the bearing at the free end and the chock and improving the processing quality of the chock.

Q3: What might lead to defects found at flanges, and how can they be corrected?

Ans: Defects at flanges can occur if the flanges are hit during mounting or if the axial impact load is too large. To correct these issues, it is important to improve the mounting operation and the loading condition.

Q4: What causes rolling elements to break and how can it be prevented?

Ans: Rolling elements can break due to excessively high impact load, development of flaking, improper or insufficient lubrication, excessive axial load or eccentric mounting of the roll neck and chock, causing roll deflection. To prevent these issues, it is crucial to improve the accuracy of mounting seals and operational procedures to avoid deflection, improve the loading condition and select proper lubricating grease to ensure sufficient lubrication.

Q5: What are the reasons for score, deformation, defect, breaking and abnormal wear on cages, and what measures should be taken?

Ans: These issues can arise from high vibrating and impacting moments, insufficient lubrication, improper mounting (resulting in roll deflection), or damage during mounting. Corrective measures include improving the loading condition, reselecting the lubricating mode and ensuring adequate lubrication, reducing mounting errors, modifying the cage design, and improving the mounting operation.

Q6: How can rust on bearings be prevented?

Ans: Rust on bearings can occur due to improper storage, dew formation in the atmosphere, or the intrusion of water and rusting matter during use. To prevent rust, it is essential to improve storage conditions, enhance sealing devices, and provide rust preventive treatment before long periods of inactivity.

Q7: What causes indentations on the raceway and how can they be addressed?

Ans: Indentations can result from the intrusion of foreign matter, shock during mounting, improper fitting, or incorrect selection of clearance. To address these issues, bearings should be thoroughly cleaned before mounting to prevent foreign matter intrusion, sealing devices should be improved, the mounting operation should be enhanced and the proper clearance group should be selected.

Q8: What leads to discoloration, deformation and deposition on bearings and what are the solutions?

Ans: These issues can arise from insufficient internal bearing clearance, improper or insufficient lubrication, excessively heavy load, or the development of other bearing damages. Corrective measures include selecting proper internal bearing clearance, reselecting the lubrication mode and ensuring adequate lubrication, reselecting the bearing type, and detecting and addressing bearing damages at an early stage.