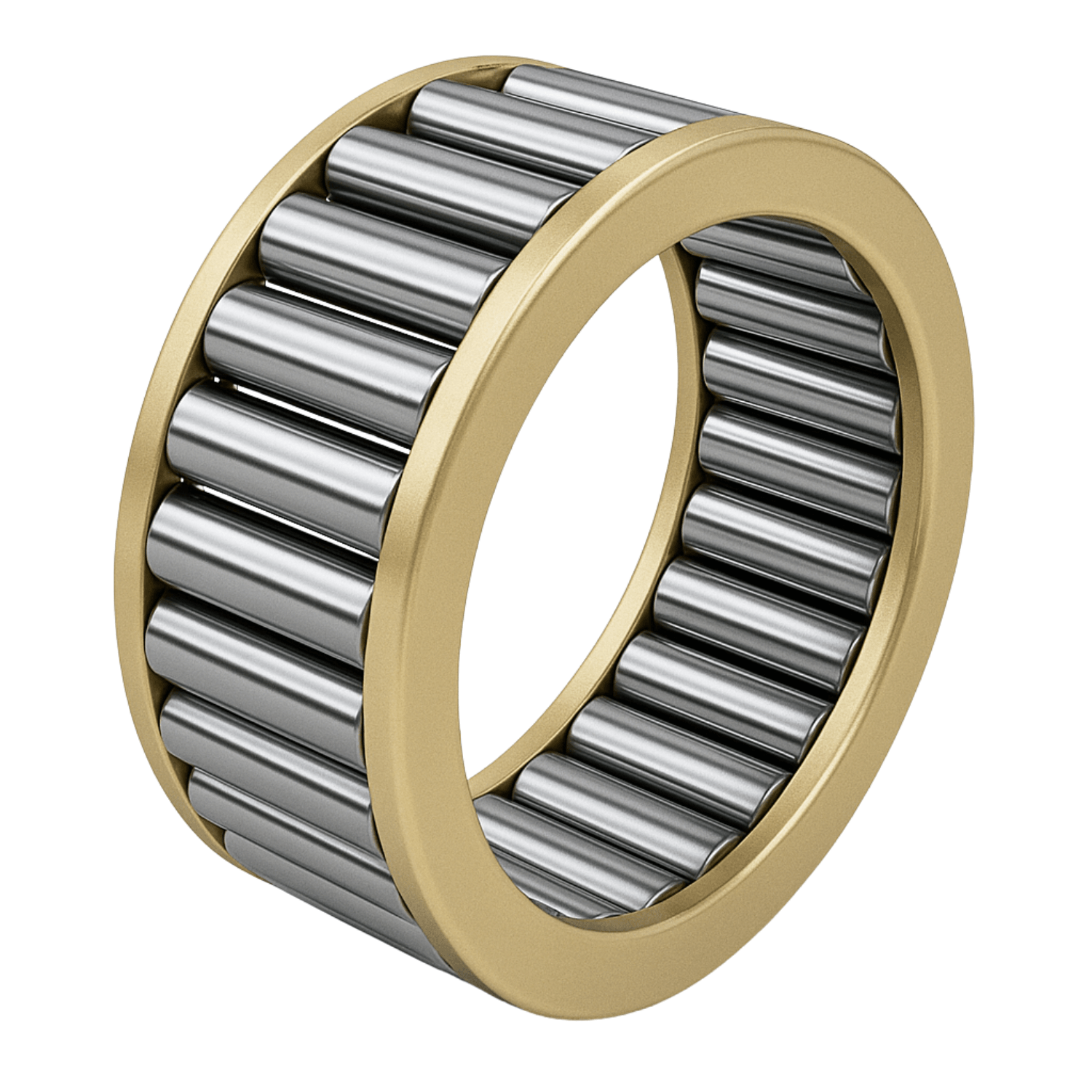

Needle Roller Bearings

Needle roller bearings are compact, high-capacity bearings that use long, thin cylindrical rollers as rolling elements. Their small cross-section and high load-bearing capability make them ideal for applications where space is limited but strength and performance are critical.

- "Compact design with up to 60% reduced cross-section compared to conventional bearings."

- "Supports high radial loads despite small size and lightweight design."

- "Capable of operating at speeds up to 6,000 RPM in optimized conditions."

Types

- Needle Roller and Cage Assemblies: Lightweight, easy to install, suitable for high-speed and high-load applications.

- Drawn Cup Needle Roller Bearings: Thin-walled outer rings allow compact installation in limited spaces.

- Solid Needle Roller Bearings: Feature machined outer rings for higher rigidity and strength.

- Thrust Needle Roller Bearings: Handle axial loads efficiently in compact arrangements.

- Combined Needle Roller Bearings: Integrate radial and thrust components for multifunctional applications.

Features & Benefits

- Compact Design: Slim cross-section saves space without compromising performance.

- High Load Capacity: Long, thin rollers distribute load effectively for heavy radial forces.

- Lightweight: Reduced material use makes them suitable for weight-sensitive applications.

- Versatility: Available in multiple types and configurations for diverse industries.

- Durability: Designed to operate under harsh conditions with long service life.

- Efficient Operation: Low friction ensures smooth performance and reduced energy loss.

Applications

- Automotive: Widely used in transmissions, rocker arms, gearboxes, and universal joints.

- Industrial Machinery: Found in pumps, compressors, construction equipment, and textile machines.

- Aerospace: Applied in flight control systems and auxiliary equipment where space and weight are critical.

- Consumer Products: Used in power tools, appliances, and compact mechanisms requiring reliability in limited space.

Selection Considerations

- Space Constraints: Ideal where compact design is a priority.

- Load Requirements: Best suited for high radial loads; axial load handling depends on thrust needle variants.

- Speed Capability: Ensure compatibility with lubrication and cage design for high-speed applications.

- Installation: Select drawn cup designs for easy press-fit assembly or solid types for added strength.

- Environment: Consider protective seals or coatings for dusty, high-temperature, or corrosive conditions.