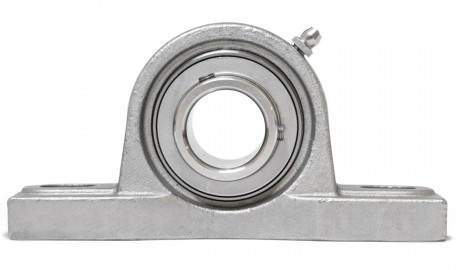

Pillow Block Bearings

Pillow block bearings, also known as Plummer block bearings, are mounted units that consist of a housing (pillow block) and a bearing insert. They are designed to provide support and rotational freedom for shafts in various industrial applications.

Types

- Ball Bearing Pillow Block Units: These units incorporate deep groove ball bearings or other types of ball bearings within a pillow block housing, suitable for applications requiring high-speed operation and moderate radial loads.

- Roller Bearing Pillow Block Units: Utilizing roller bearings (such as cylindrical or spherical roller bearings) within the housing, these units are preferred for heavier radial and axial loads and are commonly used in conveyor systems, mining equipment, and heavy machinery.

Features and Benefits

- Versatility: Accommodates various shafts, offering flexible design and installation.

- Easy Maintenance: Simplifies inspection and lubrication, reducing downtime and costs.

- Shaft Alignment: Self-aligning, ensuring smooth operation and reduced component wear.

- Sealing Options: Protects against contaminants, extending service life in harsh conditions.

- Performance & Reliability: Ensures durable, consistent operation across a wide range of applications.

Applications

- Industrial Machinery: Pillow block bearings are widely used in industrial machinery, including conveyors, fans, pumps, and agricultural equipment, providing reliable support and smooth operation.

- Material Handling: They are essential components in material handling equipment such as conveyor systems, where they support heavy loads and withstand frequent starts and stops.

- Construction and Mining: In construction and mining equipment, pillow block bearings are employed in applications requiring robust performance under challenging conditions, such as high shock loads and vibration.

Selection Considerations

- Load Capacity: Select pillow block bearings with sufficient load capacity to handle anticipated radial and axial loads based on application requirements.

- Environment: Evaluate environmental factors such as temperature, moisture, and presence of contaminants to choose bearings with appropriate sealing and protection features.

- Mounting and Alignment: Ensure proper alignment during installation to maximize bearing performance and longevity, considering factors such as shaft deflection and thermal expansion.

- Lubrication Requirements: Follow manufacturer recommendations for lubrication intervals and methods to maintain optimal bearing performance and prevent premature wear.