Tapered Roller Bearings- Single Row / Double Row / Four Row

Tapered roller bearings can manage both thrust and radial loads on rotating shafts and in housings. It consists of single, double, and four-row configurations. Customized geometries and engineered surfaces can be applied to these bearings to further enhance performance in demanding applications. The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surface and roller axes if projected would all meet at a common point on the main axis of the bearing. Tapered roller bearings consist of four interdependent components: the cone, the cup, the tapered rollers, and the cage.

Types Of Tapered Roller Bearings

Single Row Tapered Roller Bearing

- Single row taper roller bearings have low friction and are often used in pairs to support axial thrust loads on both sides.

- The advantage of a single row tapered roller bearing is its high surface area contact.

- Single row taper roller bearings are commonly used in can-wheel bearings.

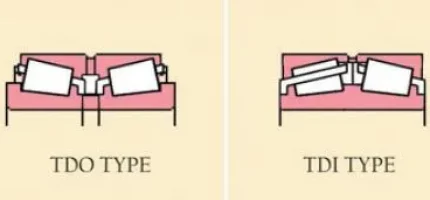

Double Row Tapered Roller Bearing

- A double row tapered roller bearing has two separate sets of tapered raceways and rollers.

- Double row tapered roller bearings are highly durable and offer excellent stiffness.

- A double row tapered roller bearing is typically used in gearboxes, hoisting equipment, rolling mills, and mining machinery.

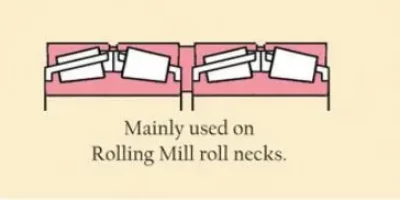

Four Row Tapered Roller Bearing

- The basic design of four row tapered roller bearing bearings is based on the observation that cones roll over each other without slipping and are capable of bearing radial and axial forces.

- In general, a four row tapered roller bearing is mounted on a roll neck with a clearance fit.

- The four-row tapered roller bearing is commonly used for low to medium speeds in rolling mills.

Features And Benefits Of Tapered Roller Bearings

- Single-row tapered bearings can accommodate radial load and axial load in one direction, and double-row tapered bearings can accommodate radial load and axial load in both directions.

- This type of bearing is suitable for use under heavy load or impact load.

- Bearings are classified into standard, intermediate and steep types, in accordance with their contact angle.

- The larger the contact angle is, the greater the bearing resistance to axial load.

- Items sized in inches are still widely used.

Application And Uses Of Tapered Roller Bearings

- The taper angles allow the bearing to handle a combination of radial and thrust loads. It is suitable for carrying heavy loads.

- Single row tapered roller bearings will be usually employed in applications that require mixed loads. Single row roller bearings may be utilized in sets. Single row roller bearings are able to be set up face-to-face, back-to-back, or in tandem to provide specific benefits based on the operating conditions.

- Double row tapered roller bearings are commonly employed in roll mills and hoisting machines, and machines used in mining industries.

- The four-row tapered roller bearings are utilized for the majority of work roll applications like rolling mills.

Tapered Roller Bearing Size Chart

| SL No. | Bearing No. | d | D | B | r (min) | Basic Dynamic Load Rating (Cr) | Basic Static Load Rating (Cor) | Limiting Speed (min-1) Grease Lubrication | Oil Lubrication | Mass (kg) Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 30203 | 15 | 35 | 11 | 0.6 | 20800 | 20700 | 10000 | 14000 | 0.081 |

| 2 | 30204 | 20 | 42 | 14 | 1 | 27000 | 27200 | 8700 | 12000 | 0.127 |

| 3 | 30205 | 25 | 52 | 15 | 1 | 31500 | 33700 | 7500 | 10000 | 0.156 |

| 4 | 30206 | 30 | 62 | 18 | 1 | 41500 | 44800 | 6500 | 8700 | 0.236 |

| 5 | 30207 | 35 | 72 | 17 | 1.5 | 55100 | 60900 | 5600 | 7400 | 0.344 |

| 6 | 30208 | 40 | 80 | 18 | 1.5 | 62900 | 69200 | 5000 | 6700 | 0.434 |

| 7 | 30209 | 45 | 85 | 19 | 1.5 | 67200 | 77400 | 4600 | 6100 | 0.502 |

| 8 | 30210 | 50 | 90 | 20 | 1.5 | 76500 | 91700 | 4300 | 5700 | 0.566 |

| 9 | 30211 | 55 | 100 | 21 | 2 | 94600 | 113000 | 3900 | 5200 | 0.732 |

| 10 | 30212 | 60 | 110 | 22 | 2 | 106000 | 127000 | 3500 | 4700 | 0.945 |

| 11 | 30213 | 65 | 120 | 23 | 2 | 128000 | 156000 | 3200 | 4300 | 1.18 |

| 12 | 30214 | 70 | 125 | 24 | 2 | 138000 | 173000 | 3100 | 4100 | 1.32 |

| 13 | 30215 | 75 | 130 | 25 | 2 | 142000 | 181000 | 2900 | 3900 | 1.42 |

| 14 | 30216 | 80 | 140 | 26 | 2.5 | 161000 | 202000 | 2700 | 3600 | 1.72 |

| 15 | 30217 | 85 | 150 | 28 | 2.5 | 182000 | 231000 | 2500 | 3400 | 2.17 |

| 16 | 30218 | 90 | 190 | 43 | 2.5 | 204000 | 261000 | 2400 | 3200 | 2.65 |

| 17 | 30219 | 95 | 170 | 32 | 2.5 | 231000 | 299000 | 2200 | 3000 | 3.2 |

| 18 | 30220 | 100 | 180 | 34 | 3 | 258000 | 338000 | 2100 | 2800 | 3.83 |

| 19 | 30222 | 110 | 200 | 38 | 3 | 324000 | 434000 | 1900 | 2500 | 5.33 |

| 20 | 30224 | 120 | 215 | 40 | 3 | 347000 | 473000 | 1700 | 2300 | 6.36 |

| 21 | 30226 | 130 | 230 | 40 | 4 | 377000 | 511000 | 1600 | 2100 | 7.24 |

| 22 | 30228 | 140 | 250 | 42 | 4 | 405000 | 538000 | 1500 | 1900 | 8.9 |

| 23 | 30230 | 150 | 270 | 45 | 4 | 466000 | 625000 | 1300 | 1800 | 10.9 |

| 24 | 30232 | 160 | 290 | 48 | 4 | 483000 | 637000 | 1200 | 1600 | 13.3 |

| 25 | 30234 | 170 | 310 | 52 | 5 | 544000 | 726000 | 1100 | 1500 | 16.5 |

| 26 | 30236 | 180 | 320 | 52 | 5 | 615000 | 870000 | 1100 | 1400 | 18.3 |

| 27 | 30238 | 190 | 340 | 55 | 5 | 729000 | 1030000 | 1000 | 1400 | 21.9 |

| 28 | 30240 | 200 | 360 | 58 | 5 | 792000 | 1120000 | 940 | 1200 | 26.4 |

| 29 | 30248 | 240 | 440 | 72 | 5 | 1230000 | 1790000 | 730 | 980 | 49.5 |

| 30 | 30252 | 260 | 480 | 80 | 6 | 1210000 | 1860000 | 650 | 870 | 64.9 |

| 31 | 30302 | 15 | 42 | 13 | 1 | 21900 | 19200 | 10000 | 14000 | 0.098 |

| 32 | 30303 | 17 | 47 | 14 | 1 | 27400 | 24500 | 9200 | 12000 | 0.081 |

| 33 | 30304 | 20 | 52 | 16 | 1.5 | 36400 | 35200 | 8300 | 11000 | 0.179 |

| 34 | 30305 | 25 | 62 | 17 | 1.5 | 48200 | 46900 | 6800 | 9000 | 0.273 |

| 35 | 30306 | 30 | 72 | 19 | 1.5 | 59600 | 60100 | 5800 | 7700 | 0.411 |

| 36 | 30307 | 35 | 80 | 21 | 2 | 76200 | 78900 | 5200 | 6900 | 0.527 |

| 37 | 30308 | 40 | 90 | 23 | 2 | 90600 | 101000 | 4500 | 6100 | 0.757 |

| 38 | 30309 | 45 | 100 | 25 | 2 | 113000 | 128000 | 4100 | 5400 | 1.01 |

| 39 | 30310 | 50 | 110 | 27 | 2.5 | 137000 | 152000 | 3700 | 4900 | 1.32 |

| 40 | 30311 | 55 | 120 | 29 | 2.5 | 149000 | 170000 | 3300 | 4500 | 1.65 |

| 41 | 30312 | 60 | 130 | 31 | 3 | 173000 | 201000 | 3100 | 4100 | 2.08 |

| 42 | 30313 | 65 | 140 | 33 | 3 | 204000 | 239000 | 2800 | 3800 | 2.56 |

| 43 | 30314 | 70 | 150 | 45 | 3 | 230000 | 273000 | 2600 | 3500 | 3.08 |

| 44 | 30315 | 75 | 160 | 37 | 3 | 250000 | 297000 | 2500 | 3300 | 3.52 |

| 45 | 30316 | 80 | 170 | 39 | 3 | 294000 | 355000 | 2300 | 3100 | 4.46 |

| 46 | 30317 | 85 | 180 | 41 | 4 | 305000 | 367000 | 2200 | 2900 | 4.97 |

| 47 | 30318 | 90 | 190 | 43 | 4 | 336000 | 407000 | 2100 | 2700 | 5.78 |

| 48 | 30319 | 95 | 200 | 45 | 4 | 317000 | 368000 | 2000 | 2600 | 6.32 |

| 49 | 30320 | 100 | 215 | 47 | 4 | 344000 | 400000 | 1800 | 2400 | 7.76 |

| 50 | 30322 | 110 | 240 | 50 | 4 | 481000 | 590000 | 1600 | 2100 | 11.4 |

| 51 | 30324 | 120 | 260 | 55 | 4 | 505000 | 611000 | 1500 | 2000 | 13.7 |

| 52 | 30326 | 130 | 280 | 58 | 5 | 563000 | 684000 | 1400 | 1800 | 16.9 |

| 53 | 30328 | 140 | 300 | 62 | 5 | 525000 | 627000 | 1100 | 1500 | 20 |

| 54 | 30330 | 150 | 320 | 65 | 5 | 616000 | 750000 | 970 | 1400 | 23.9 |

| 55 | 30332 | 160 | 340 | 68 | 5 | 742000 | 933000 | 900 | 1300 | 29.1 |

| 56 | 30334 | 170 | 360 | 72 | 5 | 762000 | 1040000 | 830 | 1200 | 34.3 |

| 57 | 30336 | 180 | 380 | 75 | 5 | 833000 | 1150000 | 780 | 1100 | 40.1 |

| 58 | 30338 | 190 | 400 | 78 | 5 | 950000 | 1210000 | 740 | 1000 | 44.8 |

| 59 | 30340 | 200 | 420 | 80 | 5 | 904000 | 1230000 | 690 | 970 | 50.6 |

| 60 | 30344 | 220 | 460 | 88 | 5 | 1260000 | 1680000 | 730 | 980 | 69 |

| 61 | 30348 | 240 | 500 | 95 | 5 | 1520000 | 2100000 | 670 | 890 | 87.3 |

| 62 | 32004 | 20 | 42 | 15 | 0.6 | 27300 | 31500 | 9300 | 13000 | 0.102 |

| 63 | 32005 | 25 | 47 | 15 | 0.6 | 30200 | 37700 | 8300 | 11000 | 0.118 |

| 64 | 32006 | 30 | 55 | 17 | 1 | 38200 | 48000 | 7000 | 9400 | 0.177 |

| 65 | 32007 | 35 | 62 | 18 | 1 | 45500 | 59400 | 6200 | 8200 | 0.231 |

| 66 | 32008 | 40 | 68 | 19 | 1 | 53500 | 71400 | 5600 | 7400 | 0.282 |

| 67 | 32009 | 45 | 75 | 20 | 1 | 62800 | 86500 | 5000 | 6600 | 0.354 |

| 68 | 32010 | 50 | 80 | 20 | 1 | 65700 | 94500 | 4600 | 6100 | 0.389 |

| 69 | 32011 | 55 | 90 | 23 | 1.5 | 84600 | 121000 | 4100 | 5500 | 0.569 |

| 70 | 32012 | 60 | 95 | 23 | 1.5 | 86100 | 127000 | 3900 | 5200 | 0.621 |

| 71 | 32013 | 65 | 100 | 23 | 1.5 | 90000 | 137000 | 3600 | 4800 | 0.664 |

| 72 | 32014 | 70 | 11o | 25 | 1.5 | 108000 | 163000 | 3300 | 4400 | 0.884 |

| 73 | 32015 | 75 | 115 | 25 | 1.5 | 110000 | 169000 | 3100 | 4200 | 0.93 |

| 74 | 32016 | 80 | 125 | 29 | 1.5 | 147000 | 225000 | 2900 | 3900 | 1.32 |

| 75 | 32017 | 85 | 130 | 29 | 1.5 | 150000 | 234000 | 2800 | 3700 | 1.38 |

| 76 | 32018 | 90 | 140 | 32 | 2 | 178000 | 276000 | 2600 | 3500 | 1.8 |

| 77 | 32019 | 95 | 145 | 32 | 2 | 182000 | 287000 | 2500 | 3300 | 1.88 |

| 78 | 32021 | 100 | 160 | 35 | 1.5 | 215000 | 344000 | 2200 | 3000 | 2.45 |

| 79 | 32022 | 110 | 170 | 38 | 2.5 | 248000 | 395000 | 2100 | 2800 | 3.12 |

| 80 | 32024 | 120 | 180 | 38 | 2.5 | 427000 | 2000 | 2600 | 2600 | 3.34 |

| 81 | 32026 | 130 | 200 | 45 | 2.5 | 340000 | 563000 | 1800 | 2300 | 5.04 |

| 82 | 32036 | 180 | 280 | 64 | 3 | 644000 | 1100000 | 1200 | 1600 | 14.1 |

| 83 | 32038 | 190 | 290 | 64 | 3 | 654000 | 1170000 | 1100 | 1500 | 14.7 |

| 84 | 32044 | 220 | 340 | 76 | 4 | 894000 | 1620000 | 940 | 1300 | 25.2 |

| 85 | 32048 | 240 | 360 | 76 | 4 | 924000 | 1720000 | 870 | 1300 | 26.8 |

| 86 | 32052 | 260 | 400 | 87 | 5 | 1170000 | 2170000 | 770 | 1000 | 39.5 |

| 87 | 32056 | 280 | 420 | 875 | 1200000 | 2280000 | 720 | 960 | 41.7 | |

| 88 | 32204 | 20 | 47 | 18 | 1 | 32500 | 34800 | 8700 | 12000 | 0.156 |

| 89 | 32205 | 25 | 52 | 18 | 1 | 39800 | 44800 | 7900 | 11000 | 0.188 |

| 90 | 32206 | 30 | 62 | 20 | 1 | 50700 | 57900 | 6500 | 8700 | 0.292 |

| 91 | 32207 | 35 | 72 | 23 | 1.5 | 69600 | 82400 | 5600 | 7500 | 0.453 |

| 92 | 32208 | 40 | 80 | 23 | 1.5 | 77700 | 90800 | 5000 | 6600 | 0.554 |

| 93 | 32209 | 45 | 85 | 23 | 1.5 | 78300 | 94100 | 4600 | 6100 | 0.587 |

| 94 | 32210 | 50 | 90 | 19 | 1.5 | 85000 | 105000 | 4300 | 5700 | 0.643 |

| 95 | 32211 | 55 | 100 | 25 | 1.5 | 107000 | 133000 | 3900 | 5200 | 0.863 |

| 96 | 32212 | 60 | 110 | 28 | 1.5 | 132000 | 167000 | 3500 | 4700 | 1.19 |

| 97 | 32213 | 65 | 120 | 31 | 1.5 | 157000 | 203000 | 3200 | 4300 | 1.58 |

| 98 | 32214 | 70 | 125 | 31 | 1.5 | 169000 | 225000 | 3100 | 4100 | 1.71 |

| 99 | 32215 | 75 | 130 | 31 | 1.5 | 174000 | 234000 | 2900 | 3900 | 1.77 |

| 100 | 32216 | 80 | 140 | 33 | 2.5 | 203000 | 271000 | 2700 | 3600 | 2.17 |

| 101 | 32217 | 85 | 150 | 36 | 2.5 | 232000 | 315000 | 2500 | 3300 | 2.8 |

| 102 | 32218 | 90 | 160 | 40 | 2.5 | 263000 | 362000 | 2400 | 3200 | 3.47 |

| 103 | 32219 | 95 | 170 | 43 | 2.5 | 311000 | 439000 | 2200 | 3000 | 4.34 |

| 104 | 32220 | 100 | 180 | 46 | 2.5 | 347000 | 495000 | 2100 | 2800 | 5.21 |

| 105 | 32304 | 20 | 52 | 21 | 1.5 | 45100 | 46700 | 8400 | 11000 | 0.239 |

| 106 | 32305 | 25 | 62 | 24 | 1.5 | 61200 | 64100 | 6900 | 9100 | 0.386 |

| 107 | 32306 | 30 | 72 | 27 | 1.5 | 82200 | 91600 | 5900 | 7900 | 0.588 |

| 108 | 32307 | 35 | 80 | 31 | 2 | 101000 | 114000 | 5300 | 7000 | 0.776 |

| 109 | 32308 | 40 | 90 | 33 | 2 | 116000 | 139000 | 4600 | 6200 | 1.06 |

| 110 | 32309 | 45 | 100 | 36 | 2 | 146000 | 180000 | 4100 | 5500 | 1.43 |

| 111 | 32310 | 50 | 110 | 40 | 2 | 176000 | 220000 | 3700 | 5000 | 1.89 |

| 112 | 32311 | 55 | 120 | 43 | 2.5 | 200000 | 250000 | 3400 | 4500 | 2.38 |

| 113 | 32312 | 60 | 130 | 46 | 2.5 | 221000 | 275000 | 3100 | 4200 | 2.92 |

| 114 | 32313 | 65 | 140 | 48 | 2.5 | 276000 | 357000 | 2900 | 3900 | 3.64 |

| 115 | 32321 | 105 | 225 | 77 | 4 | 635000 | 886000 | 1800 | 2300 | 14.9 |

| 116 | 32328 | 140 | 300 | 102 | 5 | 958000 | 1320000 | 1300 | 1700 | 33.5 |

| 117 | 32330 | 150 | 320 | 108 | 5 | 1240000 | 1790000 | 1200 | 1600 | 42 |

| 118 | 32332 | 160 | 340 | 114 | 5 | 1220000 | 1720000 | 1100 | 1400 | 47.9 |

| 119 | 32334 | 170 | 360 | 120 | 5 | 1310000 | 1830000 | 1000 | 1300 | 55.8 |

| 120 | 32336 | 180 | 380 | 126 | 5 | 1410000 | 1980000 | 960 | 1300 | 67 |

| 121 | 32338 | 190 | 400 | 132 | 5 | 1550000 | 2190000 | 890 | 1200 | 76.6 |

| 122 | 32340 | 200 | 420 | 138 | 5 | 1790000 | 2580000 | 830 | 1100 | 91 |